- Machine Information

- Machine Features & Benifits

- Machine Application

- Purchase history

- Customer Reviews

- Buyers Q & A

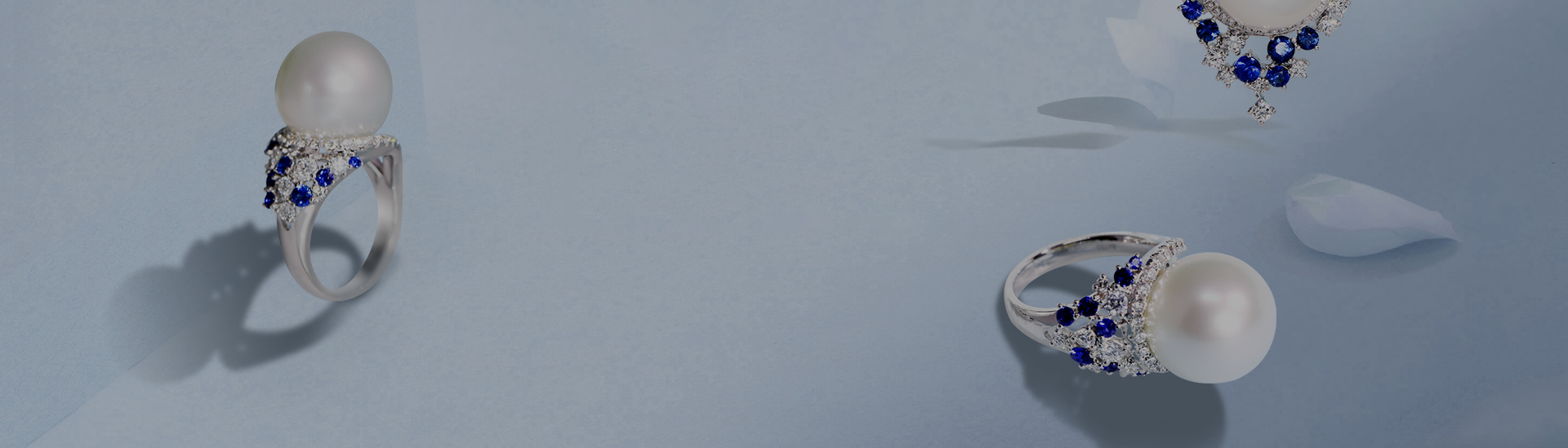

The 3D Jewelry Wax Stone Setting Machine offers high precision and user-friendly operation, specifically designed for inlaying Moissanite or Synthetic Cubic Zirconia (CZ) into wax molds. Ideal for producing trendy jewelry such as hip-hop style rings, this machine ensures efficient and accurate stone setting. Perfect for crafting detailed 925 Sterling Silver gemstone rings, it enhances both productivity and design quality in modern jewelry manufacturing.

Operation Procedures of 3D Jewelry Wax Stone Setting Machine

Step 1 : Make Silicon Jig Step 2: 3D Scanning Step 3: Make Stone Placement Step 4 : Start

CLICK HERE TO GET A QUICK QUOTATION

Technical Parameter

| Model | WD360-WAX |

| Running Distance | X: 370 , Y1 : 300 , Y 2: 300 , Z : 55, A : - 90~+90 Degree , B : 0~240 Degree |

| Stone Plate Worktable Size (mm) | 250*350 |

| Wax Mold Worktable Max Size (mm) | 8*8 |

| Stone Nozzle Quantity (pcs) | 4 |

| Accuarcy (mm) | +/- 0.05 |

| Inlaid Speed | Flat Wax Mold : 5 Stones / Second ; 3D Wax Mold : 3 Stones / Second |

| Power | 220V , 1.5KW , 50/60 Hz |

| Transmission | Screw Balling and H level Screw Balling |

| Motor | 4 AC Servo Motor and 5 Servo Motor |

| Machine Size (mm) | 680* 750 * 123 |

| Machine Weight | 250 |

Why Choose 3D Jewelry Wax Stone Setting Machine

Weldo as the leader development and manufacturers for 3D jewelry wax stone setting machine in wordwide , we implants brains and eyes into our jewelry diamond setting robot .

Strong R & D Team | |

| Led by our boss Doctor Lee , our R&D continuously drives innovation , keeping our machine technology ahead of the competition. | |

Standardized Manufacturing | |

| Our standardized manufacturing process follows the ISO 9001 quality system , ensuring high quality and precision Jewelry Wax Stone Setting Machine | |

International Technical Support | |

| From pre-sales consultation to post-sales service , our technical supports ensures reliability and boosts customer trust in selecting our 3D jewelry wax stone setting machine |

Key Specification of 3D Jewelry Wax Stone Setting Machine

|

CHAPTER 1 INTELLIGENT DATA ACQUISITION SYSTEM Of 3D Jewelry Wax Stone Setting Machine

|

|

|

|

|

|

|

|

2K Laser Scanning : By emitting sub-millimeter-level blue laser and utilizing the principle of laser triangulation, the system leverages built-in high-precision 3D algorithms to output high-frame-rate point cloud data, depth maps, and intensity images in real time with sub-micron accuracy.

3D Stone Software : By integrating point cloud data from intensity and depth maps of varying brightness, a 3D laser point cloud image is generated. Built-in geometric algorithms and deep learning capabilities assist operators in accurately positioning the diamond.

Up Camera : The upward-facing camera is used to automatically detect the position of the nozzles, eliminating the need for manual visual inspection of nozzle alignment on the wax mold. The detection images are tracked and displayed in real time on the computer for accurate monitoring.

Down Camera : The downward-facing camera is designed to accurately set the stone nozzle’s picking position, eliminating the need for manual visual alignment with the stone holes on the tray. The nozzle’s zero-point calibration and positioning can be fully tracked and monitored through the computer software via real-time camera imaging.

CHAPTER 2 : WAX STONE INLAY SYSTEM of 3D JEWELRY WAX STONE SETTING MACHINE

| ||

|

|

|

|  |  |

|

|

|

| |

| |

| |

| |

| |

|

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-